|

Densité ((kg/m)3)

|

Épaisseur ((m)

|

Longueur (m)

|

Largeur (m)

|

Pièces/emballage

|

|

24 à 96

|

0.025 à 0.1

|

0.6-1.25

|

0.6

|

5 à 18

|

|

24 à 96

|

0.025 à 0.1

|

0.6-2.4

|

1.1-1.25

|

5 à 18

|

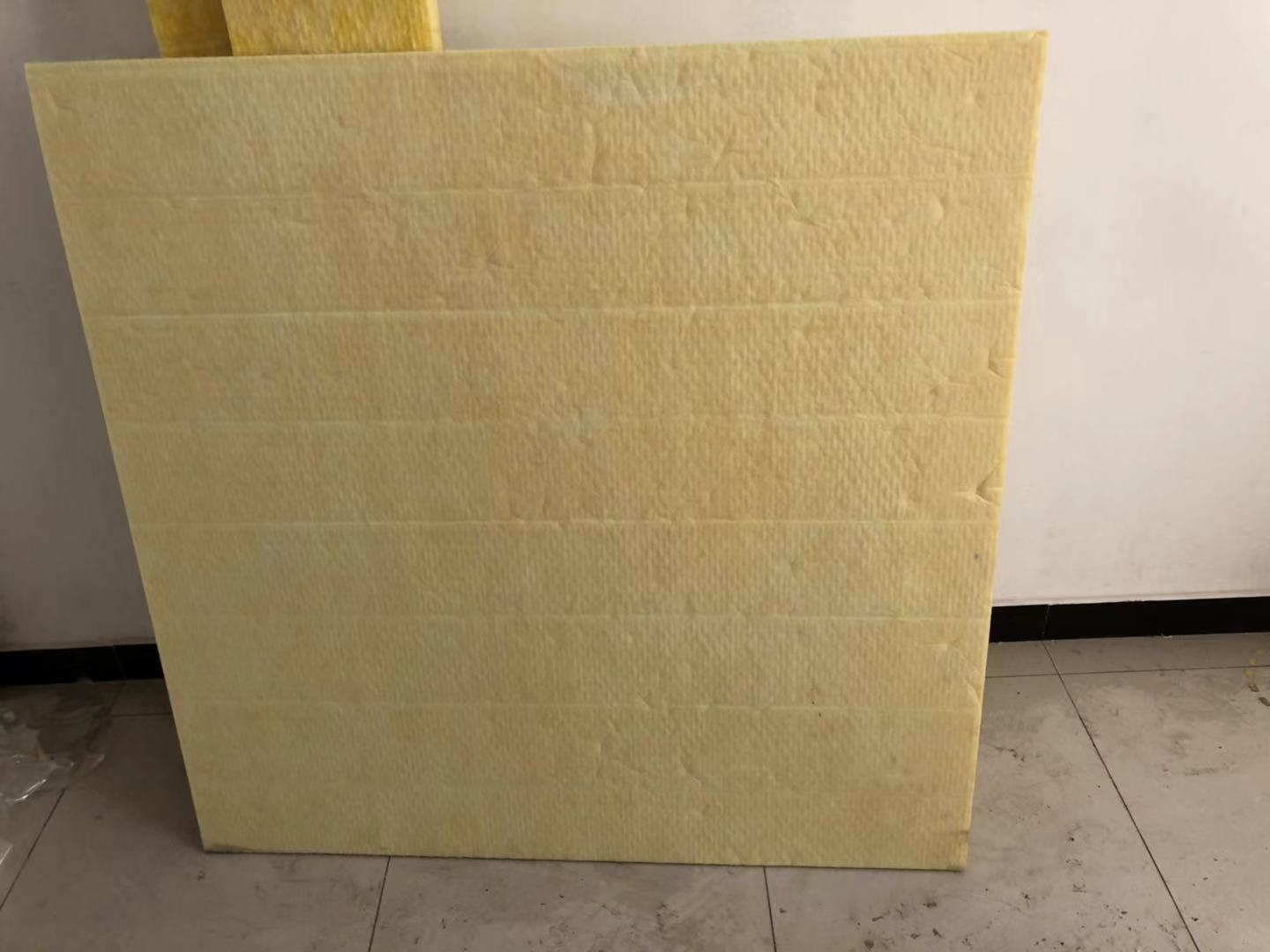

Caractéristique du produit et application de TIl est de la fibre de verre Isolement

1- Isolation des murs

Convient pour les applications murales extérieures et intérieures, il assure un contrôle stable de la température intérieure, réduit considérablement la consommation d'énergie,et améliore la capacité d'un bâtiment à s'adapter aux conditions climatiques changeantes.

2- Isolation des structures en acier

Conçu pour les installations industrielles, les entrepôts et les grandes structures en acier, il fournit une isolation thermique efficace tout en améliorant les économies d'énergie et les performances de sécurité incendie.

3.Murs de séparation intérieurs

Il sert de remplissage de cloisons intérieures légères qui combine isolation thermique et acoustique, aidant à maximiser l'espace utilisable et à assurer l'intimité des occupants.

4- Isolement des véhicules ferroviaires

Offre une gestion thermique et acoustique intégrée dans les wagons ferroviaires, améliorant le confort de déplacement et répondant aux normes strictes en matière de matériaux pour l'industrie du transport.

5.Absorption du son et isolation du bruit

Réduit efficacement la transmission du bruit dans les milieux commerciaux, industriels et résidentiels grâce à des techniques d'absorption et d'isolation, idéal pour les théâtres, les studios et les salles mécaniques

Détails de production de TIl est de la fibre de verreIsolement

ProduitEmballageDesTIl est de la fibre de verre Isolement

L'emballage habituel est un sac en plastique.

OEM est acceptable

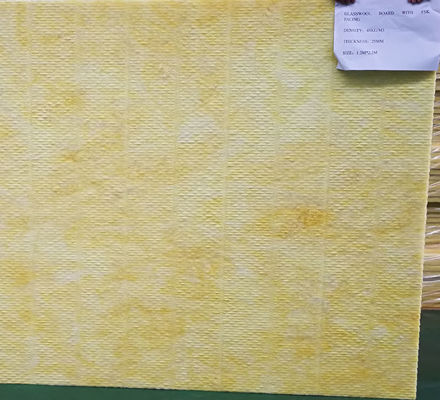

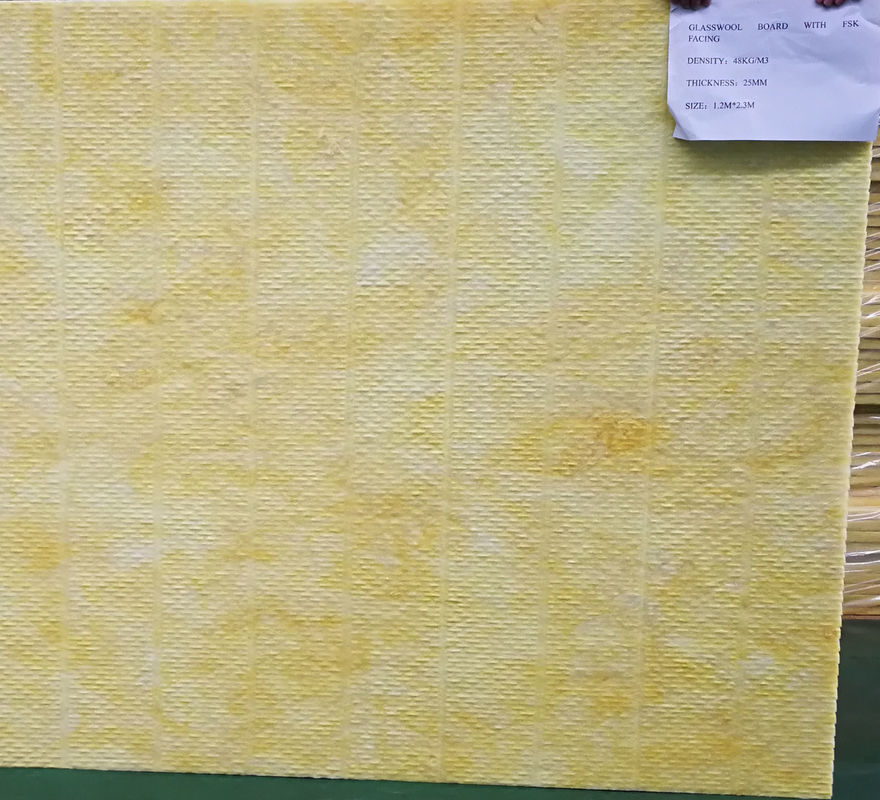

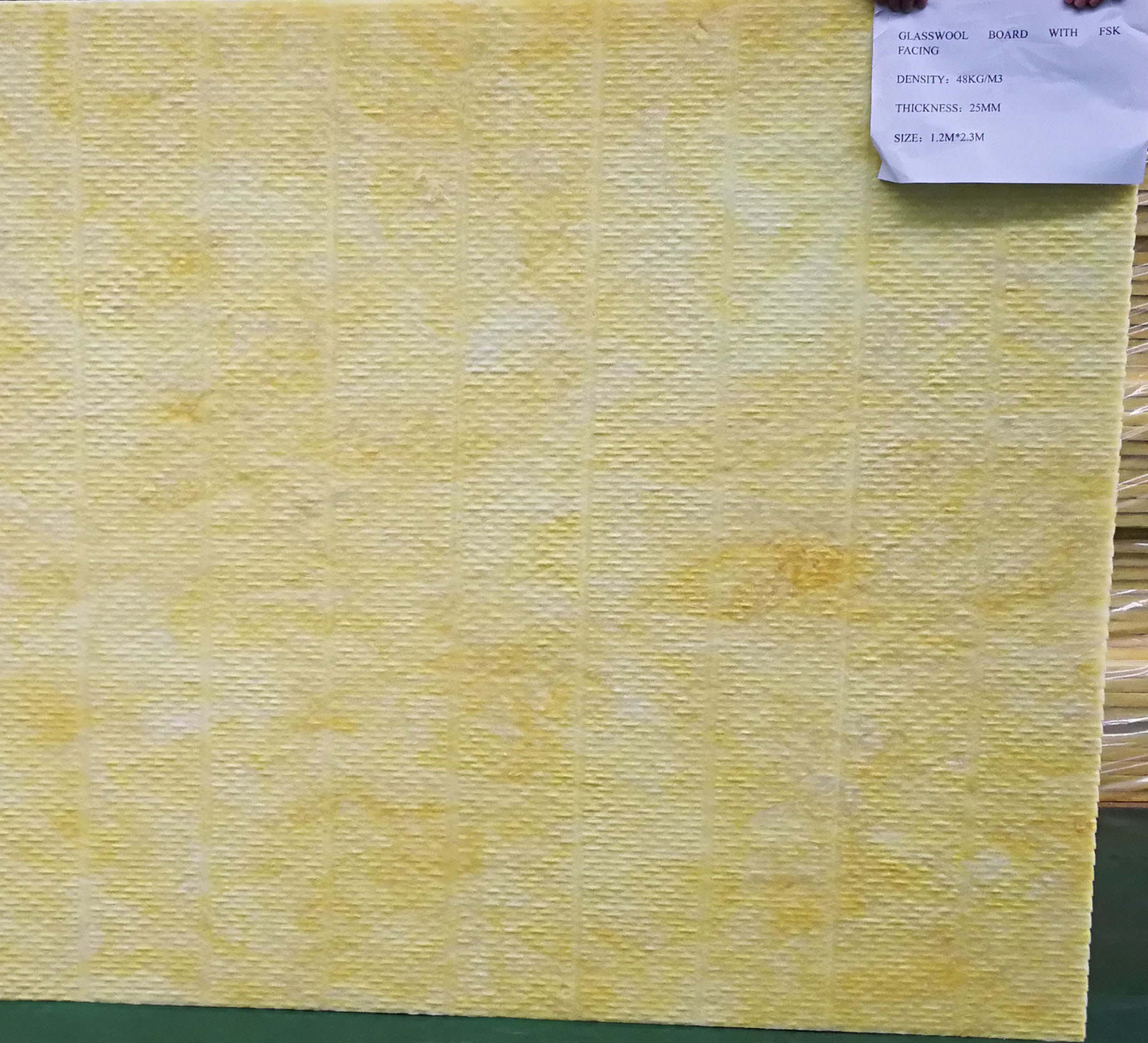

La production face à faceJe vous en prie.fTIlGUne fille.WleB. Pourle bois Isolement

1.Faisant face à la feuille de papier

2.Façade en tissu en verre d'aluminium

3.Tissus en fibre de verre

FAQ:

Q1: Comment garantir la qualité des produits?

A1: Notre équipe de contrôle qualité expérimentée inspectera la qualité du produit dans chaque processus

Q2: Comment emballer les marchandises exportées?

A2: Sac en plastique (emballage standard à l'exportation).

Q3: Quel est votre délai de livraison pour une commande de conteneur 40HC?

A3: Habituellement7 à 10jours ouvrables après la commande

Q4: Quel est votre avantage par rapport au panneau en laine de verre?

A4: La taille spéciale peut être faite selon les exigences du client.

Q5: À propos du service après-vente, comment résoudre les problèmes survenus de votre Un client étranger à temps?

R5: La garantie de nos produits est d'un an. Si nos produits ou l'emballage ont un problème de qualité, nous remplacerons ou compenserons en conséquence.

Notre service

- Garantie d'un an pour tous les produits

- Assistance technique nécessaire

- Livraison de produits de qualité avec un excellent service à temps

- Fournir une solution unique pour les produits d'isolation et de ventilation

- Fournir un service de contrôle qualité de haut niveau

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!