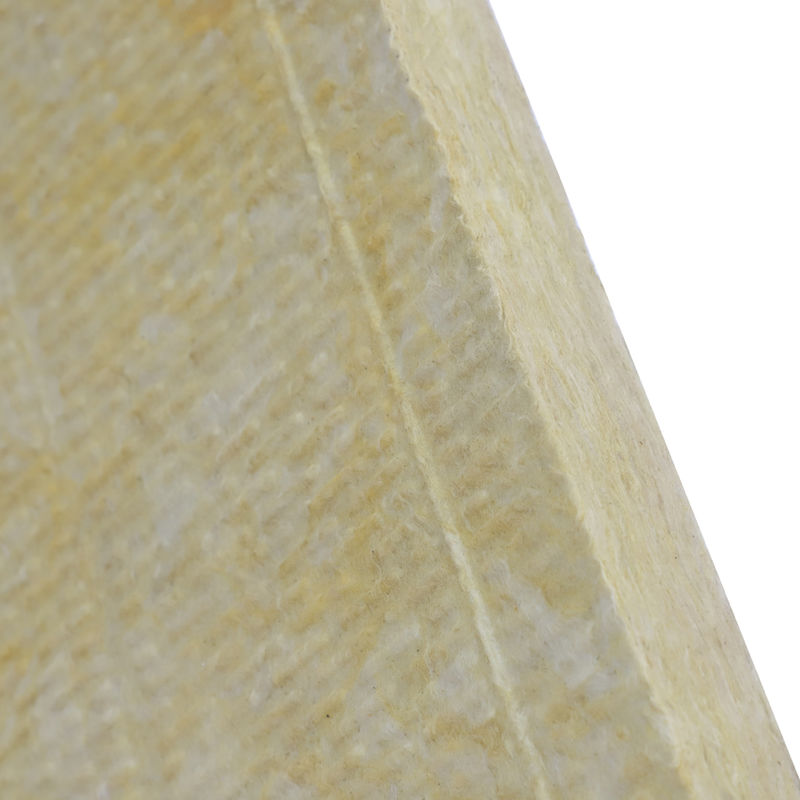

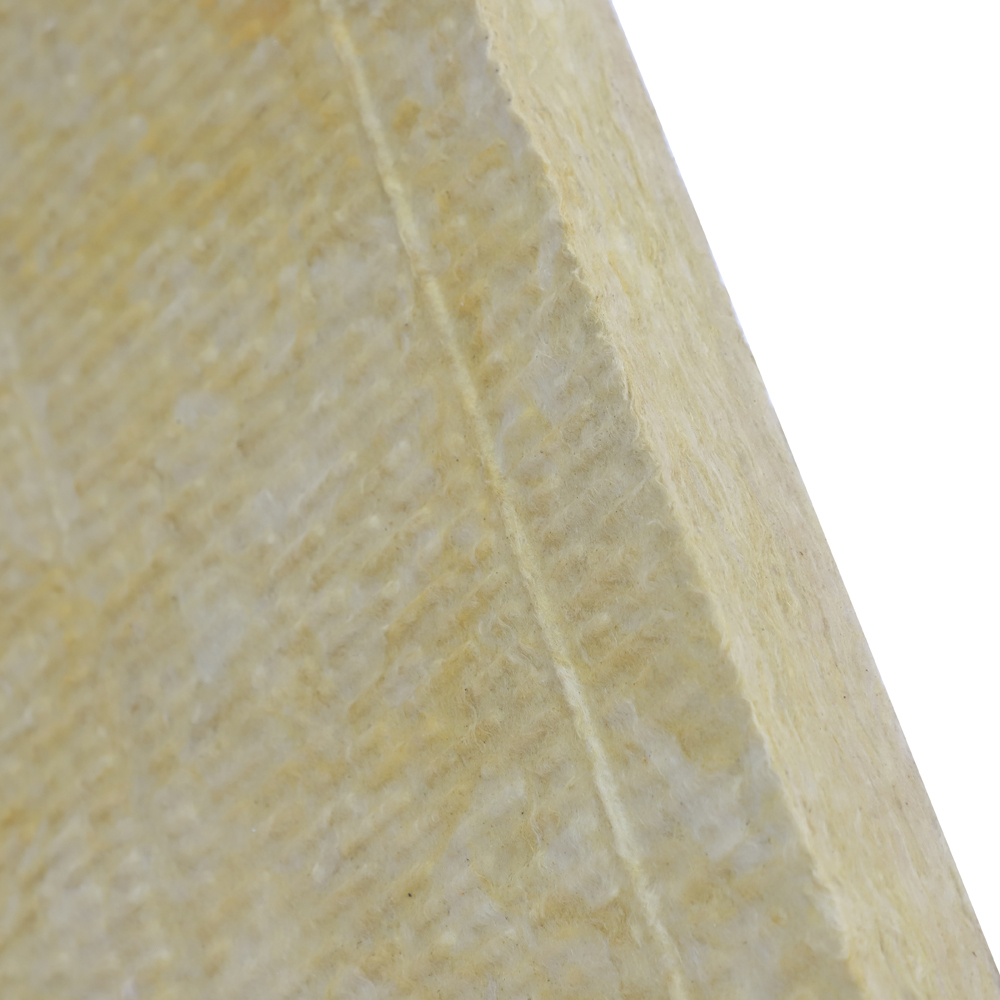

Introduction du produit du carton en laine de roche

Conçue pour des environnements exigeants, la planche en laine de roche FANRYN offre des performances exceptionnelles au feu et une stabilité thermique.le matériau est fibré et lié à la résine pour former des panneaux durables résistants à la chaleur, l'humidité et la corrosion.

Largement utilisé pour isoler les pipelines à grande échelle et les équipements industriels, ce panneau assure la conservation de l'énergie et le respect des normes de sécurité strictes.Sa faible conductivité thermique et sa structure à haute densité assurent une isolation durable même dans des conditions difficiles..

Détails de la production du produitPanneau en laine de roche

Paramètre du produit du panneau en laine de roche

|

Propriétés

|

Conseil

|

Les normes

|

|

Tolérance à la densité

|

± 10%

|

Le produit doit être présenté dans un emballage en acier.

|

|

Performance au feu

|

Non combustibles

|

Le produit doit être présenté dans un emballage en acier.

|

|

|

Réaction au feu de classe A1

|

Le produit doit être présenté dans un emballage de qualité supérieure.

|

|

Conductivité thermique

(W/mK, à 70±5°C)

|

≤ 0044

|

Le numéro de série est le numéro de série.

|

|

Diamètre de la fibre

|

7 ((+/-1) mm

|

Les produits de base doivent être présentés dans un emballage de qualité supérieure.

|

|

Contenu du tir

(taille de prise de vue)>0.25 mm)

|

≤ 12%

|

|

|

Contenu en humidité

|

≤ 0,5%

|

|

|

Contenu en matière organique

|

Jusqu'à 4%

|

|

|

Point de fusion

|

>1000°C

|

|

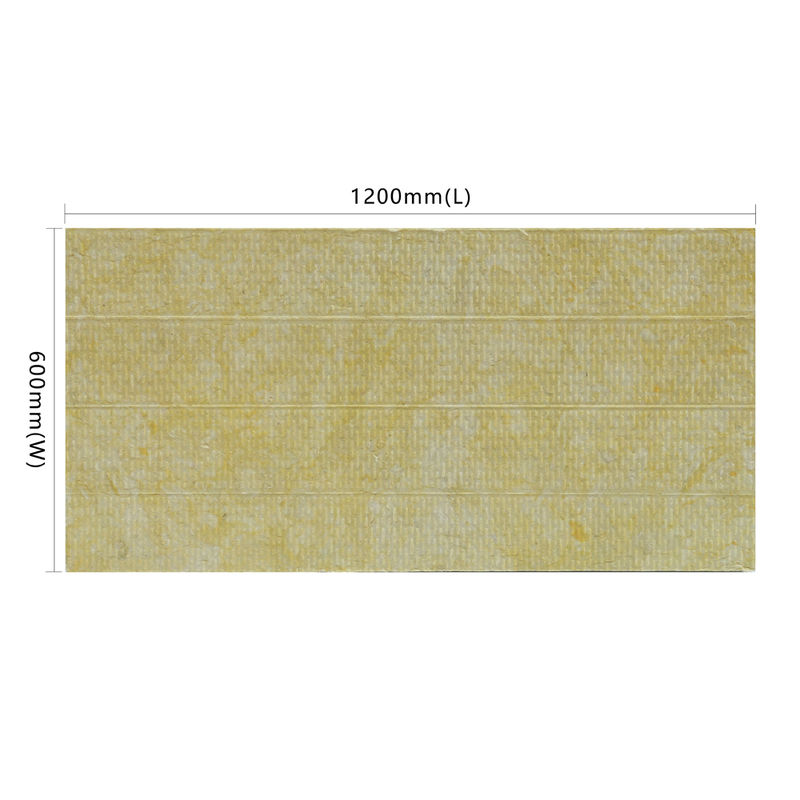

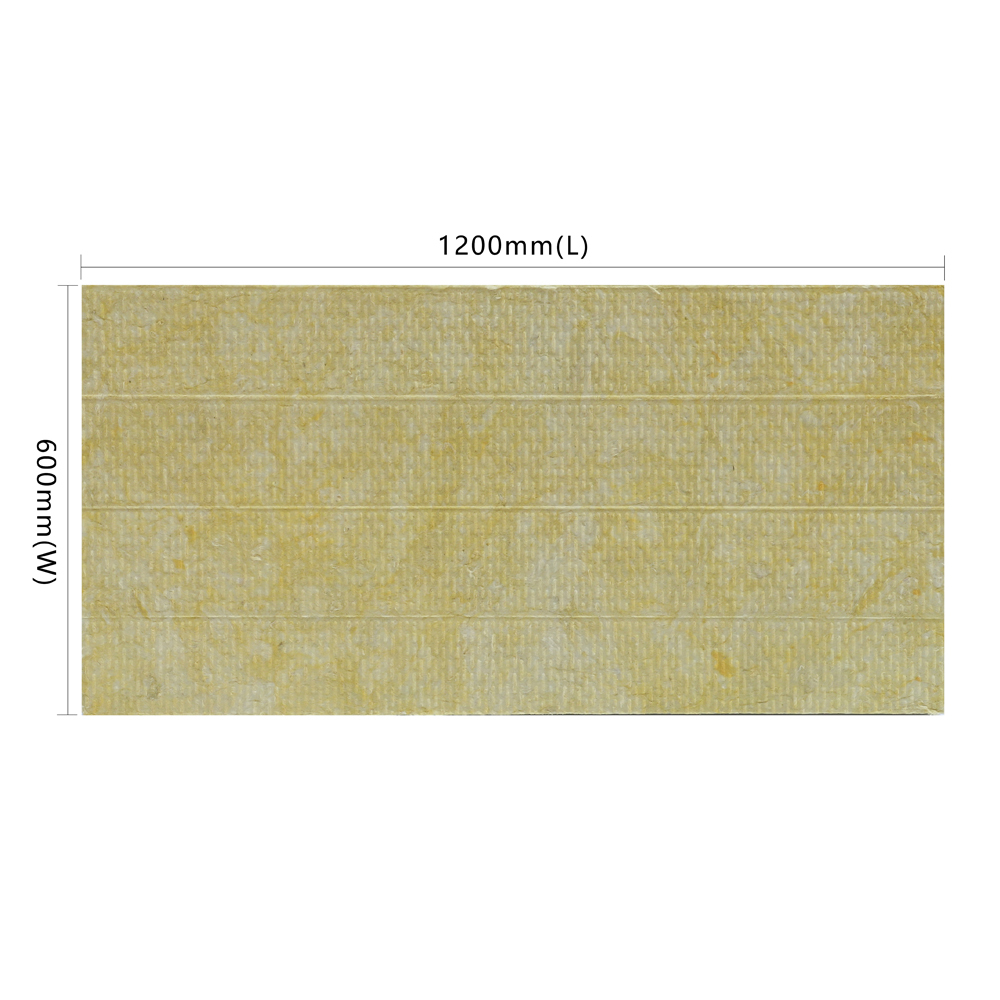

Taille du produit du panneau en laine de roche

|

Produit

|

Conseil

|

|

Densité (kg/m3)

|

40 à 200

|

|

Taille: L x largeur (mm)

|

600X1200

|

|

Épaisseur (mm)

|

30 à 100

|

Application du produit du carton en laine de roche

Enveloppes de bâtiment:Isolement des murs extérieurs pour une efficacité énergétique supérieure.

Systèmes de toiture:Isolement plat ou incliné du toit qui combat la perte de chaleur et le risque d'incendie.

Compartements intérieurs:Des murs de séparation qui améliorent l'intimité grâce à l'absorption du son.

Planchers flottants:Réduction du bruit d'impact pour des bâtiments à plusieurs étages plus silencieux.

Applications industrielles:Isolation pour les conduites de grand diamètre dans les usines et installations.

Fabrication de plaques en laine de roche

Maillage de fil

d'une épaisseur n'excédant

Tissu en fibre de verre

Emballage de production du carton en laine de roche

1.sacs en plastique

2.Sacs de rétrécissement en PE

FAQ:

Q1: Comment garantir la qualité des produits?

A1: Notre équipe de contrôle qualité expérimentée inspectera la qualité du produit dans chaque processus

Q2: Comment emballer les marchandises exportées?

R2: Sac en plastique (emballage standard à l'exportation).

Q3: Quel est votre délai de livraison pour une commande de conteneurs 40HC?

A3: 15-20 jours ouvrables habituels après la commande

Q4: Quel est votre avantage par rapport à la planche en laine de roche?

A4: Un produit spécial avec des spécifications spéciales peut être fabriqué sur commande.

Q5: En ce qui concerne le service après-vente, comment résoudre les problèmes survenus de votre client d'outre-mer à temps?

R5: La garantie de nos produits est d'un an. Si nos produits ou l'emballage ont un problème de qualité, nous remplacerons ou compenserons en conséquence.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!